Production

PRODUCTS

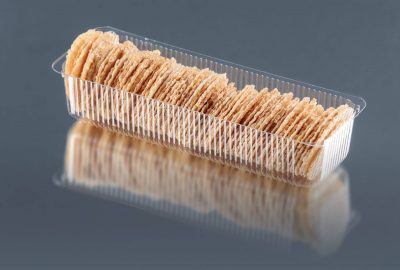

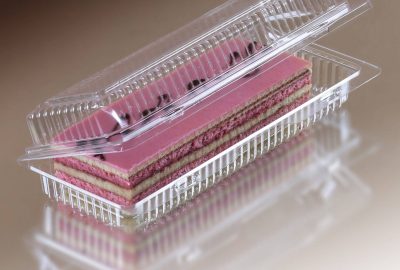

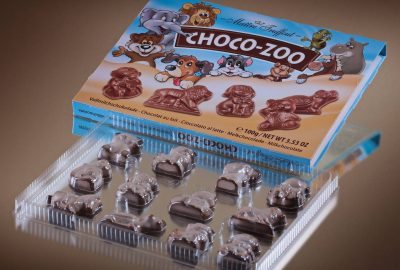

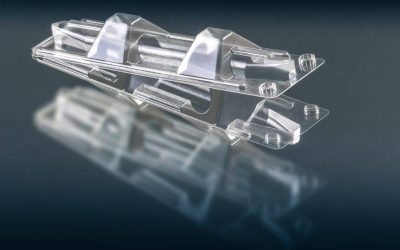

The product line consists of: plastic multi-cavity trays and inserts, plastic salad containers and punnets, hinged and locked containers, inserts for dessert, confectionery and biscuits. The range is complemented by technical blisters and small 2 ml to 50 ml a plastic bottles.

PRODUCTION

SAWIUS ’s manufacturing is focused on design, development and production plastic packaging, based on the conversion and thermoforming of PS, OPS, PET, PP and PVC foils.

In terms, the quality of products, services and jobs in an organization is established and applied a quality management system according to ISO 9001.

Production is subjected with the rules „Production process control”, which are notified all involved employees .

Modern production hall and warehouse space

They meet strict hygiene standards and our customers' requirements. The technology used is world-class by experienced and leading manufacturers of machinery and equipment: G.N. Plastics Company Limited Canada and ILLIG Maschienenbau GmbH Co. KG Germany.

Quality production facilities and their maintenance

We place great emphasis on quality production facilities, as well as on their maintenance and safe operation. The company has made great efforts to ensure that the machines meet the highest quality and safety regulations according to the latest standards. Safety of work on production facilities is declared by the Technical Inspection of the SR with certificates for the safety of the technical equipment according to Art. 13 STN EN ISO / IEC 17020.

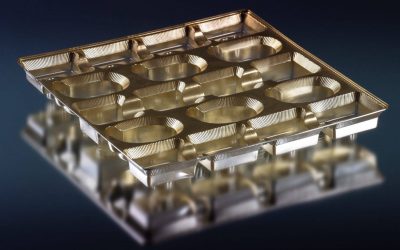

TOOLING DEPARTMENT

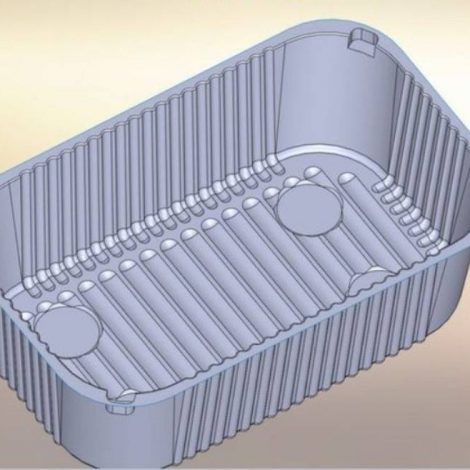

Own development team

Thanks to our own development team and tool shop, we are able to meet even the most demanding requirements of our customers. We provide our customers with comprehensive services from product development to finished tools. With our experienced team, we can meet even the most demanding wishes of our customers.

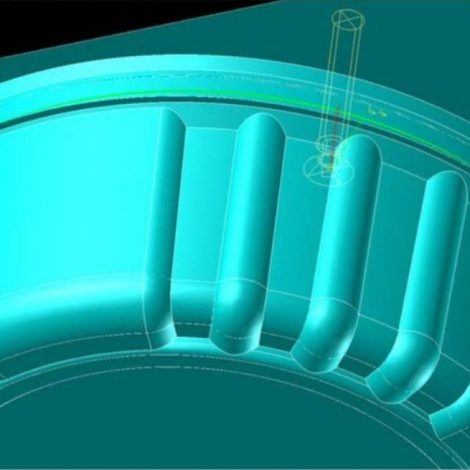

NEW CNC centers

The production of molding tools is carried out on modern computer-controlled machining centers (CNC). This mode of machining increases efficiency and quality. In tool making, all machining processes take place in a tool shop with highly qualified specialists. Through the process, we save costs for our clients and provide maximum quality.

New technology

GN800

- a newly developed high-speed and reliable thermoforming machine

- ideal for the production of high quality heat-molded plastic products from various materials such as: PP, PET, OPS, HIPS, PVC and the like.

- maximum film thickness: 2.00 mm

- has an enlarged molding area of 830 mm x 570 mm, which ensures production even in multiple forms

ILLIG

- vacuum machine for production of plastic blisters made of PET, PVC, PS, PP

- maximum molding area 500 x 350 mm

- maximum foil thickness: 1.50 mm

- with the ILLIG vacuum molding technology, it can be produced economically and efficiently, even small series as well as smaller dimensions

- technology provides all the possibilities of shaping, storing heat-molded products

Sales

We supply packaging to renowed food companies and to international markets in Europe including:

Czech republic

Hungary

Germany

Switzerland

Austria

Italy

Romania

Latvia